Suche nach einem zuverlässigen Lebensmittelverpackungsbeutel Die Wahl eines Großhändlers ist eine der wichtigsten Entscheidungen für Lebensmittelhersteller. Ein Qualitätspartner kann die Produktqualität sicherstellen, die Gesamtbetriebskosten (TCO) senken, die Konformität gewährleisten und Ihre Marke in den Regalen hervorheben.

Dieses Handbuch, geschrieben von DQ Pack, einem führendes Unternehmen im Großhandel für flexible Lebensmittelverpackungen, bietet praktische, technische und kommerzielle Checklisten, mit denen Sie Lieferanten schnell und sicher prüfen können.

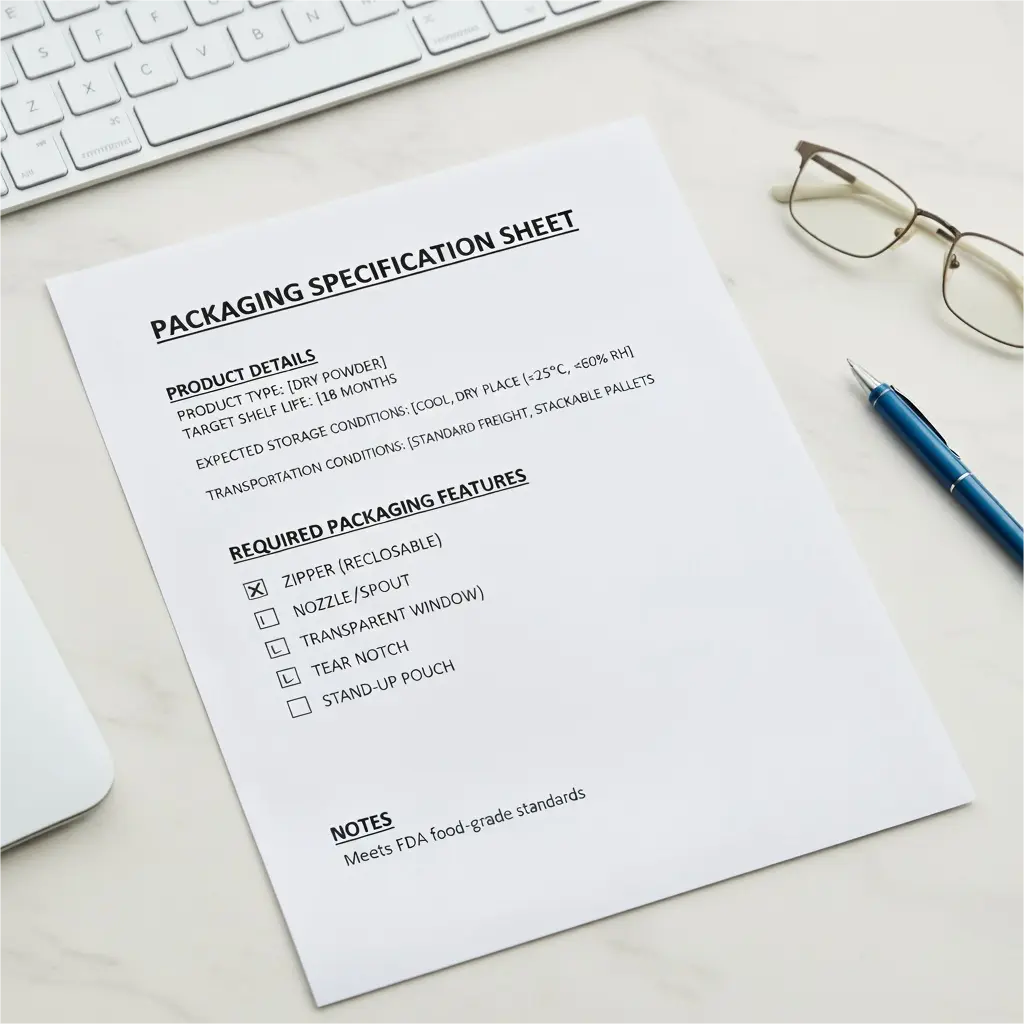

Beginnen Sie mit einer klaren Produktspezifikation

Bevor Sie sich mit dem Lieferanten in Verbindung setzen, erstellen Sie bitte ein Spezifikationsblatt, das folgende Informationen enthält: Produkttyp (trocken, flüssig, pastös), angestrebte Haltbarkeitsdauer, voraussichtliche Lager- und Transportbedingungen sowie erforderliche Merkmale (Reißverschluss, Düse, Ventil, Fenster). Wenn Ihr Produkt feuchtigkeits- oder sauerstoffempfindlich ist, fügen Sie bitte die angestrebten MVTR- und OTR-Werte hinzu.

Bitte geben Sie außerdem das erwartete jährliche Umsatzvolumen, das Umsatzvolumen in der Hochsaison und die SKU-Roadmap an. Klare Spezifikationen ermöglichen es den Lieferanten, genaue Angebote und relevante Musterempfehlungen abzugeben.

Bewerten Sie die technischen Fähigkeiten, nicht nur den Preis

Der Preis ist zwar wichtig, aber die Priorität der technischen Kompatibilität ist höher. Bitte prüfen Sie, ob der Großhändler für Lebensmittelverpackungen Erfahrung mit den von Ihnen benötigten Materialien hat (PET, BOPP, VMPET, EVOH, PA und PE/PET-Lösungen aus einem einzigen Material) und ob er MVTR/OTR-Prüfberichte für fertige Beutel vorlegt (Daten zu fertigen Beuteln > Daten zu reiner Folie).

Erkundigen Sie sich nach den Druckverfahren (Rotationstiefdruck, Flexodruck, Digitaldruck), der Farbkontrolle (Δ E-Toleranz) und der Möglichkeit, funktionale Merkmale hinzuzufügen (z. B. Online-Auslassventile, Reißverschlussdichtungen, Aufreißöffnungen und Düsen). Erkundigen Sie sich, ob der Anbieter vorgefertigte Beutel oder Rollen anbietet, die mit Ihrer Abfüllanlage kompatibel sind.

Lebensmittelsicherheit, Tests und Zertifizierungen

Zuverlässige Lieferanten müssen die Sicherheit im Kontakt mit Lebensmitteln gewährleisten. Verlangen Sie von den Lieferanten eine FDA- oder EU-Erklärung über den Kontakt mit Lebensmitteln, aktuelle Berichte über Migrations- und Schwermetalltests sowie ISO 9001-, BRC- oder FSSC 22000-Zertifikate (falls zutreffend). Stellen Sie sicher, dass die Lieferanten Sicherheitsdatenblätter und die Rückverfolgbarkeit der Chargen gewährleisten können.

Für Exportmärkte prüfen Sie bitte, ob sie die Anforderungen des Ziellandes/der Zielregion erfüllen (z. B. GB-Normen, FSMA-Anforderungen). Akzeptieren Sie keine vagen Aussagen - bestehen Sie auf der Anforderung relevanter Dokumente.

Qualitätskontrolle, Probenahme und Piloten

Geben Sie die Produktion niemals ohne eine Validierung des fertigen Musters frei. Erforderlich sind: ein Probedruck vor der Produktion, ein fertiges Muster eines leeren Beutels und ein befülltes Muster für den Probelauf. Prüfen Sie die Siegelfestigkeit (Heißklebrigkeit), Berst-/Durchstoßtests, Farbregistrierung und Haft-/Abziehversuche. Erkundigen Sie sich nach den Inline-Qualitätskontrollmethoden des Lieferanten: visuelle Inspektion, Bahnspannungskontrolle, Farbmessung und dokumentierte Fehler-/Korrekturmaßnahmenraten. Ein solider Qualitätskontrollprozess reduziert Ausschuss, Rücksendungen und Produktionsverzögerungen.

MOQ, Preisstruktur und Gesamtbetriebskosten

Verstehen Sie den Unterschied zwischen Stückpreis und Gesamtbetriebskosten (TCO). Erkundigen Sie sich nach der Mindestbestellmenge (MOQ), dem Preisniveau für Wiederholproduktionen und den Gebühren für Farbwechsel. Berücksichtigen Sie die Versandkosten (FCL oder LCL), Zölle, Lagergebühren, die erwartete Verlustreduzierung durch hochwertige Barrierefolien und den Wert, der sich durch geringere Schadensraten ergibt. Instrumente zur Aushandlung von Chargengrößen, jährlichen Verpflichtungen oder gemeinsamen Investitionen zur Senkung der Stückkosten.

Lieferzeiten, Kapazität und Skalierbarkeit

Fordern Sie den Großhändler für Lebensmittelverpackungen auf, realisierbare Zeitpläne für Probenahme, Formenbau, Produktion und Transport vorzulegen. Überprüfen Sie die Produktionskapazität der Notfallpläne der Lieferanten (Ersatzproduktionslinien, Ersatzanlagen) für Spitzen- und Worst-Case-Szenarien.

Wenn Sie planen, geografisch zu expandieren, erkundigen Sie sich bei Ihrem Lieferanten, ob er die Produktion an mehreren Standorten oder Dropshipping unterstützt. Durch eine zuverlässige Einhaltung der Lieferbedingungen lassen sich Lieferengpässe und teure Eilzustellungen vermeiden.

Logistik, Verpackung und Schadenregulierung

Bestätigen Sie die Verpackungsmethode des Beutels (Innenkarton, Palettenkonfiguration) sowie die Schutzmaßnahmen für den See- oder Lufttransport. Definieren Sie klar die FOB/CIF-Bedingungen, die Versicherungshaftung und das Verfahren des Lieferanten für Transportschäden. Erkundigen Sie sich nach historischen Schadensquoten und Beispielen für Abhilfemaßnahmen - dies kann die tatsächliche Betriebsreife widerspiegeln.

Nachhaltigkeit und Wiederverwertbarkeit

Wenn Nachhaltigkeit von größter Bedeutung ist, bewerten Sie die Einzelmateriallösungen des Lieferanten (PE oder PET), recycelte Produkte (rPET/rPE) und die aktuelle Zertifizierung der Recyclingfähigkeit. Vergewissern Sie sich, dass der örtliche Recyclingprozess von Materialien und Druckfarben übereinstimmt - verlangen Sie eine Bestätigung der Recyclingfähigkeit oder ein Zertifikat der örtlichen MRF (Materials Recovery Facility). Nachhaltige Lösungen reduzieren die Entsorgungskosten und erfüllen die Anforderungen der Einzelhändler.

Service, Kommunikation und technische Unterstützung

Ausgezeichnete Großhändler für Lebensmittelverpackungen sind auch ausgezeichnete Partner. Prüfen Sie, ob sie schnell reagieren, ob sie eine verantwortliche Person benannt haben und ob sie eine Vorabprüfung der Zeichnungen, eine Prüfung der Formschneideanlagen und Unterstützung bei der Einstellung der Abfüllanlagen anbieten.

Bestätigen Sie die After-Sales-Politik: Garantie, Zeitplan für Abhilfemaßnahmen und ob Produktionsaudits akzeptiert werden. Bei engen Produktionsplänen sind Sprachkenntnisse und Zeitzonenüberschneidungen entscheidend.

Schnell-Checkliste für Lieferanten (bei der Überprüfung verwenden)

- ✅ Produktdatenblatt erhalten und verstanden (enthält MVTR/OTR Ziele)

- ✅ Bereitstellung von Mustern fertiger Beutel und gefüllter Pilotmuster

- ✅ Zertifizierungen für den Kontakt mit Lebensmitteln und Laborberichte (FDA/EU, Migrationstests)

- QC-Prozesse dokumentiert (Siegelstärke, Farbkontrolle, Fehlerraten)

- ✅ MOQ, Preisstufen, Werkzeugkosten und TCO-Aufschlüsselung

- ✅ Vorlaufzeiten, Produktionskapazität, Notfallpläne validiert

- ✅ Offenlegung der Versandverpackungsmethode, des Schadensverlaufs und der Schadensabwicklung

- ✅ Nachhaltigkeitsaussagen, die durch den Nachweis der Recyclingfähigkeit oder den Nachweis des R-Gehalts unterstützt werden

- ✅ Zentraler Ansprechpartner und technischer Support für Artwork & Line Trials

Über DQ Pack

- Mehr als 30 Jahre Berufserfahrung: Als Großhändler für Verpackungsbeutel für Lebensmittel verwenden wir FDA-zertifizierte Materialien mit zuverlässiger Qualität.

- Umfassend OEM/ODM-Dienstleistungen: Unterstützung kundenspezifischer Formen, Größen und Düsendesigns zur Erfüllung individueller Anforderungen.

- Erweiterte Funktionen: Dazu gehören Düsen in pharmazeutischer Qualität, Hochbarrierefolien, die die Haltbarkeit verlängern, und umweltfreundliche, recycelbare Materialien.

- Hohe Qualitätsgarantie: Wir wählen strengstens Materialien aus, die den Lebensmittelstandards entsprechen, um sicherzustellen, dass jeder Beutel mit Fruchtpüree sicher und hygienisch ist und den internationalen Standards entspricht.

- Engagement für die Umwelt: Wir verpflichten uns zur Verwendung umweltfreundlicher Materialien und Druckfarben, die nicht nur dem Trend zum Umweltschutz entsprechen, sondern auch dazu beitragen, das soziale Verantwortungsbewusstsein der Marke zu stärken.

Schlussfolgerung

Die Auswahl eines geeigneten Großhändlers für Lebensmittelverpackungen erfordert eine umfassende Berücksichtigung der technischen Due-Diligence-Prüfung, der geschäftlichen Verhandlungen und des Lieferantenabgleichs. Zunächst müssen Sie ein klares Lastenheft vorlegen, Fertigprodukte und Füllmuster anfordern und eine Probeproduktion durchführen. Messen Sie die Gesamtbetriebskosten (und nicht den Stückpreis) und bestehen Sie auf der Bereitstellung dokumentierter MVTR/OTR-Daten, Zertifizierungen und Qualitätskontrollindikatoren.

Als führendes Unternehmen im Großhandel für Lebensmittelverpackungen, DQ Pack begrüßt Sie, wenn Sie sich mit uns in Verbindung setzen oder unsere effizienten Fabriken besuchen.