Pet food packaging is not just about putting a bag on it. The core is to lock in freshness and prevent leakage. Whether it’s dry food, wet food, or high-fat snacks, packaging plays a key role in maintaining product quality and protecting your brand reputation.

-2.webp)

-3.webp)

In real-world operations, even a slight mistake in packaging can lead to material leakage during transportation o product deterioration on shelves. Once consumers complain, the brand reputation you’ve built over the years can be affected.

For pet food brands, it’s better to prevent risks from the source of packaging design rather than fixing them afterwards. Based on a large number of production cases, we summarize 5 practical points to help brands avoid packaging failures.

1. Don’t Let ‘Secondary Sealing’ Become Just Decoration

Many brands equip freeze-dried products with beautiful zipper bags but overlook the durability of the zipper itself. Customers often report:

“After opening it a few times, it doesn’t fit tightly.”

This means remaining products quickly become damp and deteriorate.

Our recommendation: For products that require repeated use, invest in a reinforced explosion-proof zipper. Its teeth are tighter and harder, resisting deformation even after dozens of openings. This prevents micro-cracks at the bag opening, which are channels for oxygen and water vapor infiltration.

2. Hot Sealing Edge: An Invisible ‘Lifeline’

The strength of heat sealing depends on the temperature and elasticity of each material layer in a composite film. Using the wrong temperature or pressure may create weak edges.

At DQ PACK, before every batch, we conduct a 180-degree peel test to ensure edges are strong enough to resist internal pressure and friction during transportation.

For wet grains, low-temperature-resistant materials are crucial. Cold-chain temperature differences can make edges brittle, causing cracks like aged plastic. Poor edge sealing is one of the most common mistakes in pet food packaging.

3. Packaging Structure: Balance Protection and Practicality

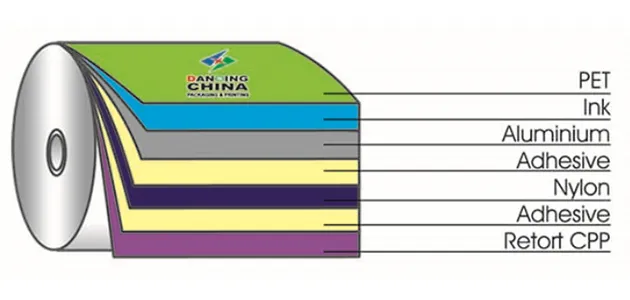

A multi-layer composite film is currently the most reliable choice. For example, PET/Aluminum Foil/PE:

- PET outer layer: sturdy and supports clear printing

- Aluminum foil middle layer: blocks oxygen, light, and moisture – essential for high-fat foods prone to oxidation

- PE inner layer: ensures strong heat sealing

For large-capacity packaging, add self-supporting reinforcement at the bottom to prevent the material from breaking during filling.

Material thickness should be ‘right,’ not just thicker. For dry grains, 50–100 microns is sufficient. For high-fat or wet grains, slightly thicker aluminum foil can improve protection.

Additional tips:

- Cooling processes and assembly line design are crucial to avoid hidden hot-edge risks.

- Nitrogen filling for high-fat products can significantly extend shelf life by removing air inside the bag.

4. Small Details Make a Big Difference

Most pet food packaging problems are hidden in the details: poor zipper selection, incorrect heat sealing parameters, or mismatched material thickness. A small mistake can trigger a chain reaction affecting the product’s quality.

5. DQ PACK: More Than Just Bags

En DQ PACK, we provide complete risk prevention solutions from material selection and structural design to production processes. Our experience solving real problems with countless pet food brands ensures that your products are safely delivered from the production line to every pet’s food bowl.

We understand that perfect packaging means peace of mind for both brands and consumers.