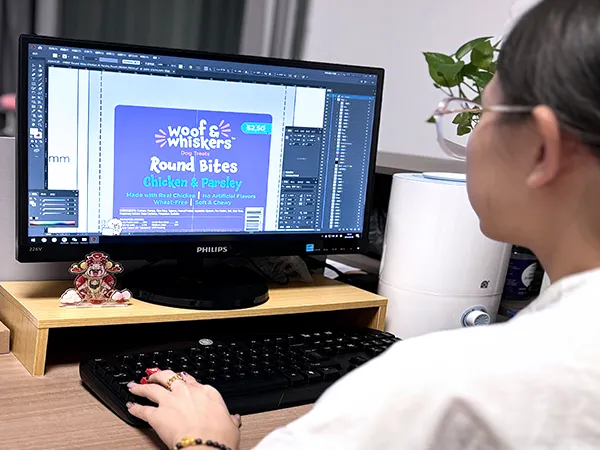

There is a common sense in the flexible packaging industry that a brand’s voice is conveyed by its packaging. Procurement teams from brands are looking for special and representative their pet food packaging bag printing.

En esta guía, DQ Pack, un professional custom flexible packaging manufacturer, breaks down print methods, finishes, ink/substrate fit, food safety, and costs to help you choose the right bag per SKU.

Why Print Choices Matter for a Pet Food Packaging Bag

Printing determines first impressions. It influences perceived quality, trust, and on-shelf conversion. But printing is not only visual: ink systems and curing methods interact with laminates and adhesives, affecting odor, migration, and downstream lamination. Selecting the correct print technology up-front prevents rework, reduces time-to-market, and keeps creative options aligned with production capability.

Printing Technologies: Pros, Cons, and Best Use Cases

Rotogravure

- Best for: high-volume runs with consistent, rich color and fine detail.

- Strengths: exceptional color saturation, smooth gradients, excellent mechanical durability for long runs.

- Trade-offs: high plate cost and longer lead time; therefore, economical only at larger MOQ.

- Use on: premium pet food packaging bag SKUs that require photographic images and tight color control.

Flexographic (flexo)

- Best for: medium-to-high volumes with faster turnaround than gravure.

- Strengths: versatile ink systems (solvent, water-based, UV), lower plate cost vs. gravure, good for solid colors and simple gradients.

- Trade-offs: slightly lower tonal range than gravure on some films.

- Use on: mainstream dry food, treats, and value-range pet food packaging bag lines.

Digital Printing

- Best for: short runs, rapid prototyping, region-specific SKUs, or personalization.

- Strengths: no plates, minimal setup, variable data (batch codes, promotions), fast artwork iteration.

- Trade-offs: higher unit cost at scale, limited varnish/embossing integration compared with analogue methods.

- Use on: test SKUs, limited editions, or serialized pet product campaigns.

Special Effects & Finishing — Create Shelf Impact

Adding finishing options elevates perceived value while remaining manufacturable:

- Matte vs. gloss lamination: matte provides a premium, tactile appeal; gloss increases color pop.

- Spot UV & tactile varnish: emphasize logos or product shots.

- Metallic/foil effects: add luxury cues (use metallized PET or hot-foil stamping).

- Clear windows: show kibble or treats — balance transparency with barrier needs.

- Embossing/debossing: tactile branding for premium ranges.

Finishing must be validated with your pet food packaging bag film and lamination method to avoid cracking, delamination, or poor adhesion.

Ink Systems and Food-Safety Considerations

Ink choice is technical and regulatory:

- Solvent-based inks provide fast drying and strong adhesion on non-absorbent films (PET, metallized film), but require VOC abatement and careful odor control.

- Water-based inks (flexo) reduce VOCs and improve workplace safety; modern formulations deliver much-improved adhesion on treated films.

- UV-curable inks offer instant cure and vivid colors, but need compatibility checks for subsequent lamination and food-contact authorization.

- Low-migration inks are mandatory when ink comes into contact with food or when inner layers could transfer odor or chemicals; request certificates and migration test data from the printer.

Always require the supplier Declaration of Compliance (DoC) and Certificates of Analysis (CoA) for inks and varnishes. For export markets, check the FDA (US), EU materials regulation, and local limits for heavy metals and restricted substances.

Substrate and Lamination Compatibility

A pet food packaging bag is typically a laminate: each layer provides a distinct function (printability, barrier, sealability, puncture resistance). Typical combinations include PET/AL/PE, PET/NY/PE, and BOPP/PE.

Key checks:

- Surface treatment (corona) level must match the ink type for adhesion.

- Thermal profiles: Some inks require high-temperature drying that can affect underlying coatings or adhesives.

- Post-print lamination: Ensure inks are fully cured before lamination to avoid contamination and delamination.

- Window placement: Plan printing and lamination to avoid seal areas and maintain barrier integrity.

Work with your manufacturer to run press trials and adhesion/peel tests on the selected laminate before committing to full production.

Minimum Order Quantities (MOQ), Lead Times, and Cost Drivers

Printing method heavily affects MOQ and lead time:

- Rotogravure: higher plate cost, lower per-unit cost at high volumes. Typical MOQs are the highest, but unit economics are best for large runs.

- Flexo: moderate MOQ and balanced lead time; cost-efficient for frequent SKUs.

- Digital: lowest MOQ and fastest turnaround; higher per-unit cost.

Other cost contributors: number of print colors, special effects, lamination type, and quality-control sampling. Plan SKU portfolios (premium vs mainstream) to optimize printing strategy across product lines.

Sustainability and Eco-Printing Options

Brands increasingly require greener production:

- Water-based inks and solvent-free lamination reduce VOCs and emissions.

- Mono-material films (PE/PE, PP/PP) enable film-stream recycling; design artwork and varnish choices to maintain recyclability.

- PCR content in non-food-contact layers supports circularity claims.

- Reduced ink coverage/spot color strategies lower material inputs and printing energy.

Ask your manufacturer for LCA or carbon estimates for competing print+laminate solutions to quantify trade-offs.

Artwork, Color Control, and Prepress Best Practices

To reduce rework and minimize color variation:

- Provide vector artwork and Pantone/CMYK targets; specify substrate and desired finish.

- Approve digital proofs and physical press proofs.

- Use color-management processes (ICC profiles) and a signed-off color check list for multi-SKU consistency.

- Plan registration and barcodes for automatic feeding and pouch forming.

A clear prepress package reduces delays during the first runs of any pet food packaging bag.

Choosing the Right Manufacturer

Select a partner who offers:

- In-house printing and lamination expertise across multiple technologies.

- Strong QC: inline inspection, peel and seal testing, and migration testing.

- Regulatory support: DoC/CoA, export experience, and food-contact verification.

- Flexibility: digital capability for short runs and gravure/flexo for larger runs.

- Sustainability credentials: solvent-free options, mono-material design experience.

Request technical samples (printed with your artwork on candidate laminates) and run accelerated shelf-life and odor tests before final sign-off.

Conclusión

DQ Pack es un professional custom flexible packaging manufacturer with in-house production dedicated to delivering precise and scalable soluciones personalizadas de envasado flexible. Our operations are built around internationally recognized safety and compliance frameworks, ensuring consistent quality, process control, and supply reliability.

By managing production directly at the factory level, we support brands with stable lead times, controlled specifications, and dependable manufacturing performance—making DQ Pack a factory partner you can rely on.