The last decade has seen the demand for consumer packaging change, with traditional rigid packaging (i.e., metal cans and glass bottles) being increasingly replaced by flexible, sustainable, and responsive flexible packaging. From pharmaceuticals to food, flexible packaging for food, beverages, and medication products is increasing and becoming the go-to option for brands seeking cost savings, compliance with environmental regulations, and meeting evolving consumer requirements.

Flexible packaging market leaders like DQパック are leading this shift by introducing custom flexible packaging with new materials, sustainable design, and customized services. This article discusses the competitive advantages of flexible packaging in four aspects: cost optimization, environmental gain, consumer experience, and market sensitivity.

Cost Optimization: Light and Efficient Logistics

Rigids are bulky, fragile, and costly to ship and hold inventory. Flexible packaging, however, including stand-up pouches, スパウトポーチそして zipper pouches, is lightweight and compact. Compressing these kinds of materials is easy, so they can be stacked in high-density formats to reduce shipping costs and carbon emissions.

For example, DQ PACK’s label zipper bags can be folded and easily shipped. Flexible packaging manufacturers also help brands to optimize shelf space utilization and minimize product damage. Such logistics advantages are achieved throughout the supply chain, optimizing overall efficiency and reducing overall operating costs.

Environmental Value: Circular Economy and Sustainable Materials

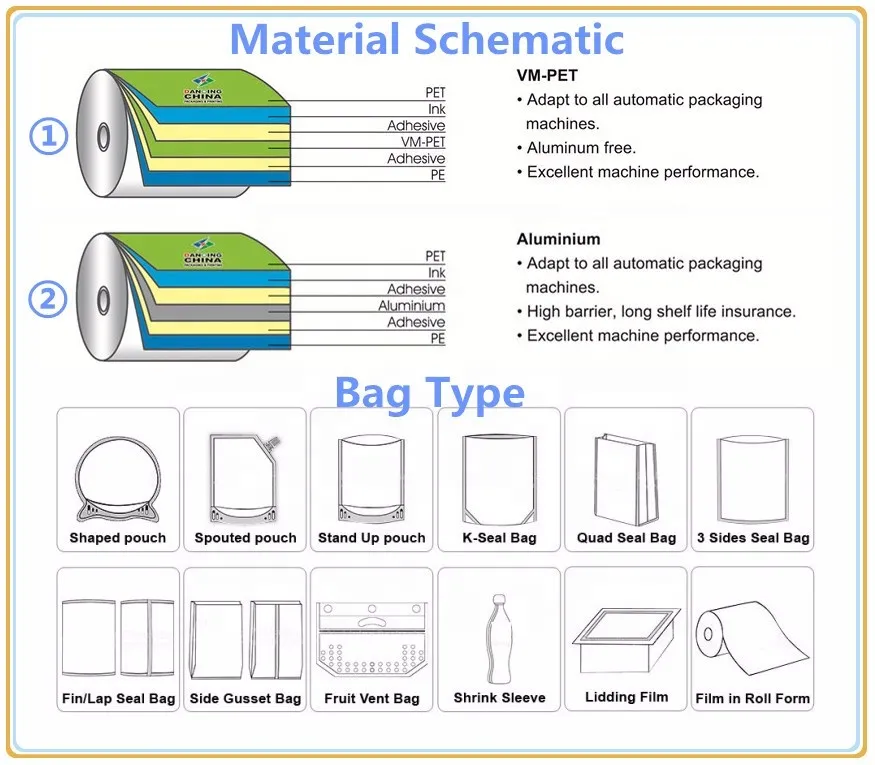

In the wake of the world’s movement towards sustainability and carbon reduction, green flexible packaging is now a powerful brand differentiator. Flexible packaging businesses nowadays focus on single-material pack formats, like recyclable PE or PP constructs, which are consistent with EU and FDA recycling regulations.

Compared to multi-layer structures found in traditional rigid packs, one-material sustainable flexible packaging is easier to recycle and produces less waste in the environment. DQ PACK, for instance, boasts biodegradable package solutions and solvent-free lamination. By reducing the use of materials through lightweight and product feature optimization, like resealable closures, brands can further reduce the use of resources and become appealing to eco-conscious consumers.

User Experience: Functional and Scenario-Based Design

Today’s consumers desire not only product protection but also smart packaging features that enhance daily usage convenience and engage emotionally. Flexible packaging allows functional and scenario-based customization for convenience and safety enhancement.

For example:

- Portability: Squeezable pouches are ideal for the outdoors, allowing one-handed control.

- Child Safety: Zipper closures inhibit accidental opening.

- Precision: Spouted pouches offer controlled dispensing, ideal for liquid or semi-liquid contents.

- Display Value: Stand-up pouch bags give excellent on-shelf presence and visibility.

Rigid packaging, on the other hand, has a form factor that is permanent and limited in use contexts. The flexibility of custom flexible packaging makes it ideal to serve niche consumer needs and lifestyle trends.

Market Adaptation: Technological Innovation and Customization

In a competitive B2B market, packaging is not just about protection—it’s identity. Flexible packaging manufacturers like DQ PACK enable brands to transform rapidly through continuous innovation and bespoke design solutions.

- Barrier Technologies: DQ PACK designs high-barrier films that extend product shelf life, perfect for flexible packaging for food and pharmaceuticals.

- Advanced Printing: High-resolution flexographic and gravure printing optimizes visual impact and supports bespoke printed flexible packaging.

- Custom Engineering: From size and shape to functionality and material content, DQパック works with customers to develop custom-designed packaging solutions that differentiate on the shelf and advance brand strategy.

With capabilities such as these, flexible packaging suppliers transform packaging from a mere container into a strategic marketing vehicle.

Conclusion: Brand Innovation Depends on Flexible Packaging

Whereas inflexible packaging once ruled in terms of durability and high-end feel, it is increasingly being usurped by flexible packaging, which better addresses the concerns of modern brands and consumers. From cost savings and sustainability to convenience and market responsiveness, 軟包装 has been a key part of modern product strategy.

If your company is looking to advance its packaging solutions, DQパック-a reliable flexible packaging manufacturer with more than 30 years of experience—provides total services ranging from material development, structural design, to market-oriented tailoring.

As the trend moves toward sustainable, efficient, and user-driven packaging, 軟包装 may hold the key to realizing higher levels of consumer interaction and operational effectiveness.