答えはイエスだ。. フレキシブル・プラスチック包装 は、材料が単一でリサイクル設備が完備していればリサイクル可能だが、全体的なリサイクル率はまだ低く、これは材料構造、リサイクル技術、インフラなど複数の要因に左右される。プラスチック循環経済に世界的な注目が集まる中、企業の責任と技術革新が軟包装のリサイクル能力の継続的な向上を促している。.

フレキシブル・プラスチック包装とは?

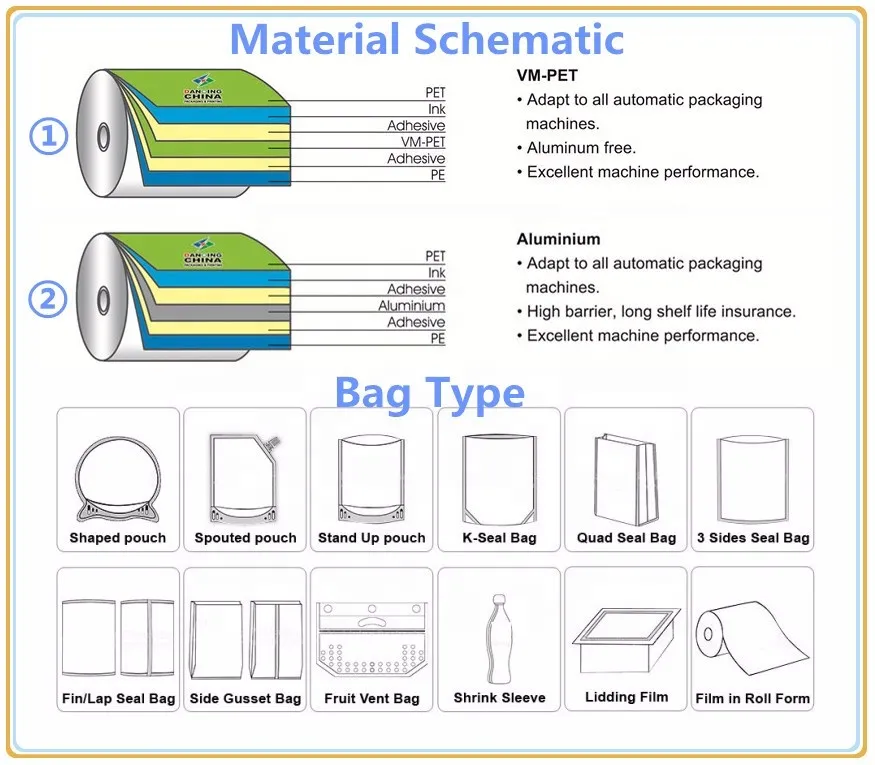

フレキシブルプラスチック包装とは、以下のような柔軟なフィルムで構成された、様々な形状の包装形態を指す。 ポリエチレン(PE)、ポリプロピレン(PP)、ポリエステル(PET). .一般的な製品には、立体袋、平底袋、軟包装ロール、真空袋、小型包装袋などがある。軽量、高いバリア性、印刷の多様性、輸送の容易さなどの長所により、食品・飲料、化粧品、医薬品、日用化学品などに広く使用されている。.

軟包装のリサイクルの難しさと現状

複雑な素材構造

多層複合フィルム(PET/アルミ/PEなど)はバリア性に優れているが、層の分離が難しく、リサイクル工程に大きな課題をもたらす。.

低いリサイクル率

カナダのデータによると、軟包装は市場の47%を占めているが、実際のリサイクル率は2%以下である。.

Plastics Pactの報告書では、米国におけるプラスチック包装のリサイクル率は13.3%に過ぎないと指摘している。.

不十分な設備と意識

多くの地域では、軟包装の分別収集・分別システムが整っておらず、リサイクルに対する一般市民の意識を強化する必要がある。.

世界の動向と規制が後押し

持続可能な包装市場が急成長

世界の持続可能な包装市場は、2023年の$2,760億米ドルから2034年には$5,580億米ドルに成長し、年平均複合成長率は7%を超えると予想されている。.

拡大生産者責任(EPR)

欧州連合(EU)、カナダ、そして多くの国々が相次いでEPR規制を導入し、生産者に包装のライフサイクル全体に対する責任を求め、企業にリサイクルしやすい包装を設計するよう促している。.

サーキュラー・エコノミー・ロードマップ

複数の業界連合(Canadian Plastics Pactなど)は、軟包装の循環経済戦略を発表し、2030年までにリサイクル率と再利用率を大幅に向上させるという目標を掲げている。.

リサイクル技術と革新的ソリューション

シングル・マテリアル・デザイン

PE単層またはPP単層包装を推進し、リサイクルプロセスを簡素化する。.

水性インクと無溶剤ラミネート

水性印刷インキと無溶剤ラミネーション技術を使用し、リサイクル工程での化学汚染を低減する。.

高度な選別とケミカル・リサイクル

近赤外(NIR)選別技術と化学分解技術を組み合わせ、混合フィルムの効率的な分離と再利用を実現する。.

DQパックの持続可能なリサイクル包装の実践

中国をリードするカスタムフレキシブルパッケージングとフレキシブルプラスチックパッケージングメーカーとして、DQ PACKはリサイクル性の分野でイノベーションを探求し続けています:

- 単一素材構造の最適化:DQ PACKは主にPE/PP単層構造を推進し、包装材料が全過程でリサイクル可能であることを保証する;;

- 高性能無溶剤ラミネート:VOC排出量を削減するため、4つの先進的な無溶剤ラミネーション生産ラインを所有;;

- グローバル品質認証:ISO9001-2018、FDA、SGS、BV複数の認証を取得し、120カ国以上に輸出され、国際的なリサイクルと安全基準を満たしている;;

- フルリンクOEM/ODMカスタマイズ:構造設計、校正、印刷からバックエンドのリサイクルソリューションのドッキングまで、ワンストップサービスを提供します。.

DQパックを選ぶ理由

- 経験と規模:30,000 ㎡のスマート工場、6つの自動印刷生産ライン、4つの無溶剤ラミネーションライン;;

- 研究開発と設計の利点:10年以上の業界経験を持つR&Dチーム、自由な構造、アートワーク、ラベルデザイン;;

- グリーン・イノベーション・ドライブリサイクル、可視化ログ、エコ素材開発への継続的な投資;;

- 信頼できるグローバルサポートヨーロッパ、アメリカ、東南アジア、中東市場をカバーする物流ネットワーク、迅速な対応;;

- 深いカスタマイズ能力小ロットの試作から大量生産まで、フルサイクルのニーズに対応します。.

概要

フレキシブル・プラスチック包装は、循環型経済の実現に向けて大きな可能性を秘めているが、複雑な構造、低いリサイクル率、不十分なインフラといった課題に依然として直面している。規制の推進、技術革新、企業責任を通じて、業界はリサイクル可能で循環型への転換を加速させている。中国の軟質プラスチック包装サプライヤーと軟質プラスチック包装メーカーの好ましいパートナーとして、, DQパック は、単一素材のデザイン、環境にやさしいインク、無溶剤ラミネーション、包括的なOEM/ODM能力を備えた実用的なリサイクル可能フレキシブル・パッケージング・ソリューションをグローバルブランドに提供し、より環境にやさしい未来に向けて共に歩んでいます。.