Introduction: Laminating Films – The Invisible Champion of Modern Packaging

As a professional laminated films manufacturer in China, DQ PACK specializes in developing and producing custom laminated films for various industries, including food, pharmaceuticals, and daily chemical products. In the rapid development of modern packaging technology, laminated films have quietly become an indispensable “invisible champion” across major sectors. Whether it’s supermarket shelves packed with snack foods or pharmaceutical items requiring high barrier protection, laminated films—thanks to their multi-layer structure and reliable performance—are widely favored.

Definition and Basic Structure of Composite Film

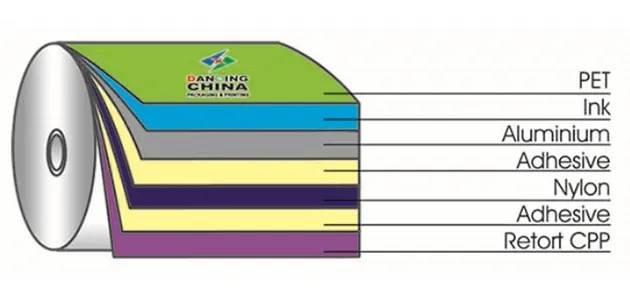

The so-called composite film is made of two or more film materials with different properties bonded by dry laminating, extrusion laminating, or solvent-free processes. It typically consists of a base material (e.g., PET, BOPP), a barrier layer (e.g., aluminum foil, EVOH), and a heat-sealing layer (e.g., PE, CPP). Each layer enhances the film’s mechanical properties, barrier performance, and processability.

Why Are Laminated Films the Industry’s First Choice?

Compared to single-material films, custom laminated films offer an optimized combination of strength, temperature resistance, oxygen and moisture barriers, and superior printability. These features are especially critical in industries like food packaging, where freshness, safety, and visual appeal must all be maintained.

Core Applications of Laminated Films in Food Packaging

Freshness and Shelf-Life Extension: How to Keep Out Oxygen and Moisture with High-Barrier Technology?

One of the main causes of food spoilage is oxidation and moisture. High-performance custom laminated films extend product shelf life by effectively blocking oxygen and moisture with barrier materials such as aluminum foil or PVDC-coated PET. In packaging nuts, coffee, or dairy products, laminated film structures can maintain extremely low oxygen transmission rates, significantly reducing oxidation risks.

High Temperature and Freezing Resistant Applications: The Role of Laminated Films in Instant Foods and Cold Chain

Instant foods often undergo heat sealing, microwaving, or high-temperature sterilization, demanding strong thermal resistance. Laminated films with PET/AL/CPP structure offer excellent heat stability. For frozen products, PE or EVA layers in the laminated film help prevent cracking and embrittlement at low temperatures, ensuring safe storage and transport.

Brand Display and Printing Adaptability: High Gloss and Customized Design

Laminated films not only protect the product but also serve as a key tool for brand communication. Whether using glossy or matte finishes, high-definition gravure printing on custom laminated films allows for vivid color reproduction and eye-catching visual impact. The excellent printability of these films gives designers more creative flexibility to express brand identity.

How to Choose the Right Laminating Film? Analysis of Key Factors

Material Selection Based on Product Needs

Different packaging needs require different film structures. The nature of the product, shelf life, and storage environment (ambient, chilled, or frozen) all influence film selection. For example, PET/AL/PE films offer excellent barrier and puncture resistance for items like sauces or retort pouches. For lightweight snacks or dry fruits, BOPP/CPP structures are often preferred for cost-efficiency.

Customized Suggestions for Chips and Puffed Food Packaging

For chips and puffed snacks that require high moisture resistance and aroma retention, a recommended option is BOPP/VMPET/CPP laminated film. The outer BOPP layer provides smooth printability, the metallized film layer enhances the oxygen and moisture barrier, and the CPP sealing layer ensures durability and integrity. Such custom laminated films also support high-speed automatic filling and sealing processes.

Conclusion: Laminated Film – A Bridge Between Functionality and Brand Value

From enhancing shelf life and resisting environmental stress to delivering outstanding visual impact and customization potential, custom laminated films play a vital role in modern flexible packaging. With growing global awareness of sustainability, recyclable laminated structures are now leading a new trend in eco-friendly packaging solutions.

As a leading China laminated packaging films supplier, DQ PACK offers end-to-end solutions, including structural consulting, material selection, and sustainable innovation. Whether you need moisture-resistant snack bags, retort pouches, or frozen food films, our custom laminated films are engineered to protect your product and elevate your brand.

👉 Looking for high-performance laminated packaging that aligns with your product vision? Choose DQ PACK—your reliable laminated film partner.

-2.webp)

-5.webp)

-1.webp)