In the modern food packaging industry, retort pouch packaging is now one of the most effective, longest-lasting, and most convenient methods of preserving and conveying ready-to-eat food. As consumers develop greater interest in shelf-stable, high-temperature resistant, lightweight, and eco-friendly packaging, food manufacturers more and more embrace flexible retort pouch packaging as a smart alternative to traditional cans and bottles.

One of the leading retort pouch manufacturing firms, DQ PACK is expert in developing premium, customizable, and recyclable retort pouch packaging solutions for global food and beverage companies.

What is a Retort Pouch?

Heat-resistant food retort pouches are composite plastic flexible packages capable of withstanding temperatures greater than 100°C. They are typically produced by specialized processes laminating multiple layers of material (such as PET, AL, CPP). They exhibit good heat sealability, crush resistance, and barrier qualities. The package remains stable in high-temperature sterilization processes without rupturing or leakage. It is widely used for processing and preservation of ready-to-eat foods such as vacuum-sealed stews, instant rice, and canned food substitutes. It is alternatively called a “soft can” because it provides the same shelf life as cans but is lightweight and simple to ship.

This advanced-technology retort pouch packaging is appropriate for ready-to-eat foods, soups, sauces, seafood, and pet food. The pouch is placed in a retort sterilizer after it is sealed, where microorganisms are destroyed by steam and pressure, offering safety for food and extending shelf life — no refrigeration needed.

As an experienced retort pouch manufacturer, DQ PACK ensures to comply with global food safety standards such as ISO22000, FDA, and SGS to provide customers with assured, export-quality packaging solutions.

The Structure of Retort Pouch Packaging

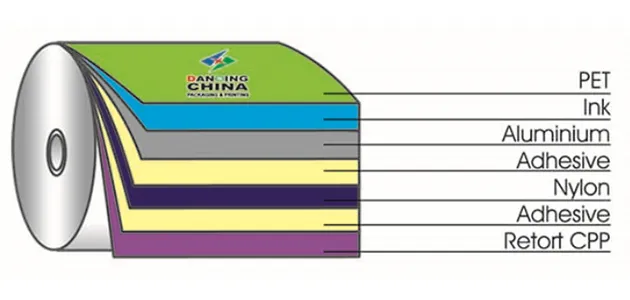

The structure of a retort pouch is what makes it work and durable. A standard retort pouch package typically has three or more laminated layers:

- Outer Layer (PET): Offers mechanical strength and also good printability.

- Middle Layer (Aluminum Foil or Nylon): Contains a high-barrier layer, which keeps light, oxygen, and moisture out.

- Inner Layer (CPP): Offers heat sealability and direct food contact safety.

Being a professional retort pouch manufacturer, DQ PACK utilizes advanced solvent-free lamination technology to ensure perfect adhesion of layers, wherein product integrity remains uncompromised under extreme sterilization pressure. Our precise manufacturing process ensures consistent sealing performance and excellent visual appearance — both paramount determinants for international food brands.

Key Advantages of Retort Pouch Packaging

Extended Shelf Life

Retort pouch packaging keeps food safe and fresh for as long as 24 months without cooling. This is ideal for export markets as well as shipping long distances.

Lightweight & Cost-Effective

Compared to metal cans or glass jars, retort pouches save on shipping weight as well as storage space by a large margin, thus saving on logistics as well as warehouse costs.

High Barrier Protection

The multilayer film structure serves to seal out air, light, and moisture penetration, maintaining food’s original flavor, aroma, and nutritional value.

Eye-Catching Branding

Full-color printability allows manufacturers to present dense graphics and personalized logos in direct view on the pouch, maximizing visibility at retail.

Customizable Design

With years of experience as a retort pouch manufacturer, DQ PACK has various sizes, shapes, and print varieties to accommodate a range of food items — from family packs to single-serve meals.

Common Applications of Retort Pouch Packaging

The versatility of retort pouch packaging makes it suitable for a wide range of food and non-food applications, including:

Ready-to-eat meals and soups

Sauces, curries, and condiments

Meat and seafood products

Baby food and instant rice

Pet food and treats

Food producers and OEM factories around the world choose DQ PACK as their retort pouch manufacturer because we ensure product safety, professional packaging design, and full compliance with international export regulations.

Retort Pouch vs. Traditional Canned Packaging

More and more brands are transitioning from metal cans to retort pouch packaging for both practical and marketing reasons.

| Feature | Retort Pouch | Canned Packaging |

|---|---|---|

| Weight | Lightweight | Heavy |

| Shelf Life | 12–24 months | 12–24 months |

| Cost | Lower logistics cost | Higher transport cost |

| Branding | Full-surface printing | Label only |

| Sustainability | Recyclable options available | Limited recyclability |

Recyclable Retort Pouches of DQ PACK towards a Greener Tomorrow

As sustainability is a leading force in global trends for packaging, DQ PACK feels privileged to be a pioneer retort pouch manufacturer leading the way to environmentally friendly choices.

Our recyclable retort pouch packaging options replace traditional aluminum layers with high-barrier PE or PET materials, maintaining integrity and heat resistance with reduced environmental footprint. Through solvent-free lamination and reduced plastic usage, our recyclable pouches allow brands to cut carbon emissions and deal with environmental compliance in export markets.

These environmentally friendly retort pouch packaging solutions, as well as protecting your products, serve to advance your company’s green image —enticing consumers who are environmentally conscious and want to do the right thing.

Why Choose DQ PACK as Your Retort Pouch Manufacturer

With over 30 years of flexible packaging experience, DQ PACK has built a strong global reputation as a reliable retort pouch manufacturer.

We offer:

- 6 advanced printing lines and 4 solvent-free lamination lines

- OEM/ODM customization for all types of retort pouch packaging

- Free samples and low minimum order quantities

- Global export to 120+ countries

- Certifications: ISO22000, FDA, BV, SGS, and GMC

Our team provides full packaging consultation, from material selection to final printing. Every pouch undergoes strict quality inspection to ensure sealing strength, visual quality, and sterilization performance meet international standards.

When you work with DQ PACK, you’re not just choosing a supplier — you’re partnering with an experienced retort pouch manufacturer dedicated to delivering flexible, sustainable, and high-performance packaging.

Conclusion: The Future of Food Packaging Is Flexible

The future of food packaging is flexibility, convenience, and sustainability — and retort pouches deliver all three. They are lightweight yet durable and are revolutionizing the storage, shipping, and selling of food worldwide.

If you’re a business in search of high-quality, sustainable, and customized packaging solutions, DQ PACK is your retort pouch manufacturer of choice. Our team is ready to help you design and produce retort pouch packaging that enhances shelf life, protects your product, and fits your sustainability goals.

Contact DQ PACK today to receive free samples and start your custom packaging process with one of the most reliable retort pouch manufacturers in the industry.

-1.webp)

-1.webp)

-4.webp)

-2.webp)