مقدمة

كوجبة خفيفة شهيرة, عبوات الحلوى يجب ألا يضمن نضارة المنتج وسلامته الصحية فحسب، بل يجب أن يكون له تأثير بصري يجذب المستهلكين. وكما حزمة DQ, مع 32 عامًا من الخبرة المهنية في مجال تغليف الحلوى المخصصة وإنتاج أكياس تغليف الحلوى، نحن ندرك جيدًا متطلبات التغليف الخاصة للحلوى المختلفة، مثل مقاومة الرطوبة ومقاومة الأكسجين ومقاومة التمزق وغيرها من الخصائص. نحن نقدم خدمات تصنيع المعدات الأصلية وتصنيع المعدات الأصلية وحاصل على شهادات دولية مثل هيئة الغذاء والدواء الأمريكية، BRC، RoHS, إلخ. يتم تصدير منتجاتنا إلى أكثر من 140 دولة في جميع أنحاء العالم، مما يضمن أن كل حل من حلول تغليف الحلوى الصديقة للبيئة يلبي أعلى معايير الجودة.

اختيار المواد الأساسية لأكياس تغليف الحلوى المخصصة

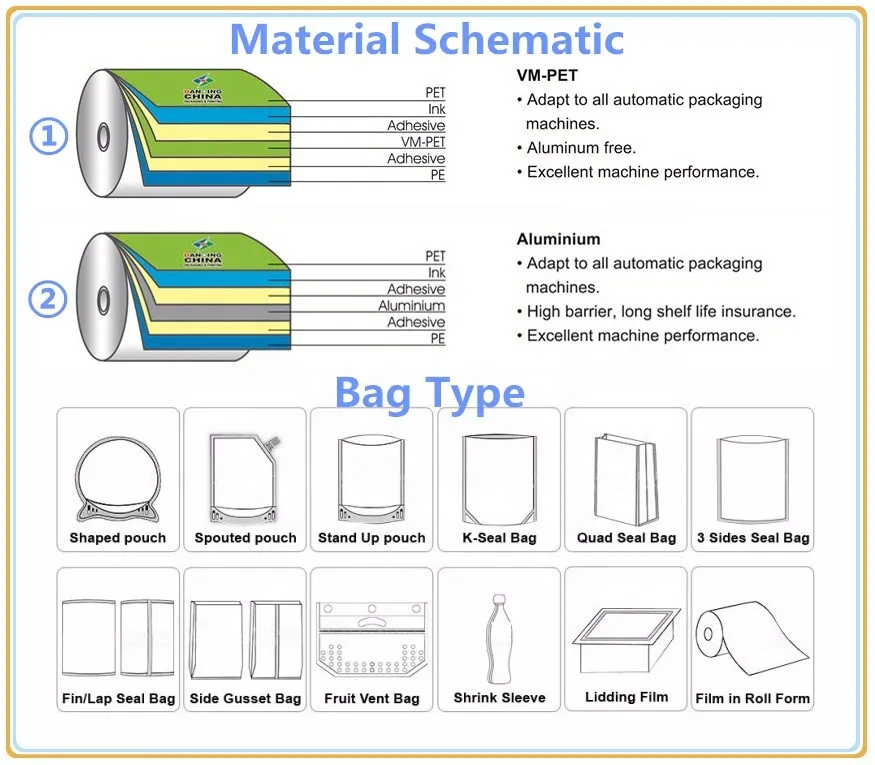

في مجال تغليف الحلوى المخصص، نستخدم مواد مركبة متعددة الطبقات لتلبية الاحتياجات المختلفة:

البولي إيثيلين (PE):

يتميز بالمرونة الجيدة وخصائص الختم الحراري، ويمكن استخدامه كمادة طبقة داخلية لملامسة الحلوى مباشرة، مما يضمن سلامة الطعام.

بولي بروبيلين (BOPP/CPP):

يتميز البولي بروبيلين ثنائي المحور (بولي بروبيلين ثنائي المحور) بشفافية عالية وتأثير طباعة جيد، ويستخدم عادةً للطبقات الخارجية؛ أما البولي بروبيلين المصبوب (CPP) فهو مقاوم للحرارة ومناسب للختم الحراري.

بوليستر (PET):

قوة عالية ومقاومة للاهتراء ومناسبة لأكياس تغليف الحلوى التي تتطلب شفافية عالية وطباعة رائعة.

غشاء مطلي بالألومنيوم (VMPET/VMCPP):

يتميز بلمعان معدني ويعزز خصائص الحاجز ويحسن من المظهر المرئي للتغليف. ويُستخدم عادةً في صناعة الحلوى الغنية بالدهون مثل الشوكولاتة.

تصميم الهياكل المركبة

تقدم DQ PACK العديد من الحلول الهيكلية المركبة بناءً على خصائص الحلوى المختلفة:

هيكل عادي (مثل BOPP/CPP):

مناسبة لمنتجات مثل الحلوى الصلبة وحلوى الفاكهة التي لا تتأثر بسهولة بالرطوبة، بتكلفة منخفضة وشفافية عالية.

بنية عالية الحاجز (مثل PET/AL/PE):

إضافة طبقة من رقائق الألومنيوم تحجب الأكسجين والرطوبة والضوء بشكل فعال، وهي مناسبة للحلوى مثل الشوكولاتة وحلوى الحليب المعرضة للأكسدة والتلف.

هيكل مطلي بالألومنيوم (مثل PET/VMPET/PE):

تجمع بين خصائص الحاجز العالي والجاذبية الجمالية، وهي مناسبة لتغليف الحلوى الراقية المخصصة.

عوامل رئيسية أخرى في عبوات الحلوى المخصصة الصديقة للبيئة

بالإضافة إلى المواد والهيكل، تهتم DQ PACK أيضًا بالتفاصيل التالية لضمان الجودة الممتازة لأكياس تغليف الحلوى:

- الختم: يتم استخدام تقنية الختم الحراري المتقدم أو تقنية السحاب لمنع رطوبة الحلوى أو التصاقها.

- عملية الطباعة: يتم استخدام الطباعة بالحفر عالي الوضوح لضمان وجود أنماط ساطعة وغير باهتة تفي بمعايير الحبر المخصص للطعام.

- تصميم وظيفي: توفير حلول مخصصة مثل الفتحات سهلة الفتح، والأكياس القائمة بذاتها، وعبوات العبوات الصغيرة لتعزيز تجربة المستخدم.

- مقاومة درجات الحرارة: توفير حلول تغليف الحلوى الصديقة للبيئة للحلوى الخاصة مثل الشوكولاتة المقاومة لدرجات الحرارة العالية أو المنخفضة.

الخاتمة

اختيار محترف مورد تغليف الحلوى المخصص أمر بالغ الأهمية. حزمة DQ, بخبرة 32 عامًا من الخبرة في هذا المجال، توفر أكياس تغليف الحلوى عالية الجودة التي تلبي الشهادات الدولية مثل FDA و BRC و RoHS، وما إلى ذلك، للعملاء في جميع أنحاء العالم. سواءً كان هيكل BOPP/CPP للحلوى العادية أو التغليف المطلي بالألومنيوم عالي الحاجز للشوكولاتة، يمكننا توفير حلول تغليف حلوى صديقة للبيئة مخصصة لضمان نضارة المنتج وسلامته وجمالياته. نحن ندعم خدمات تصنيع المعدات الأصلية وتصنيع التصميم الشخصي ونقوم بتصدير منتجاتنا إلى أكثر من 140 دولة، مما يجعلنا شريكك الموثوق به في مجال التغليف المرن. مرحبًا بكم في الاتصال بنا للحصول على حلول تغليف حصرية!